1. Specification

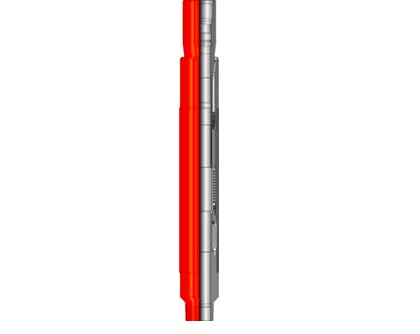

Pipe O.D.: 25.4mm~88.9mm(1.0" - 3.5" )

Pipe Wall Thickness: 1.90mm ~ 6.35 mm

Grade: CT55 ~ CT110 ( the minimum yield strength: 379Mpa ~ 758Mpa ; X52C ~ X90C

Individual Length: 8000m Maximum

Reel Diameter: 3800mm Maximum

2. Standards:

API RP 5C7 < Coiled Tubing in Oil and Gas Wells Recommended Practice>

API SPEC 5ST< Specfications of Coiled Tubing>

API SPEC 5LCP < Coiled Line Pipe >

3. Brief Introduction

Coiled tubing mainly applies to workover,logging, drilling, completion and gathering tranmission field etc. It has many

advantages such as small occupation area, high-efficiency, convenient in disassembling and assembling, reservior protection,

production increasing, safety and enviromental protection as well as wide application range which is incomparable with

common tubing.

Jaya Petro-tech supplys high quality of coiled tubing with the first world-class coiled tubing production line in Asia. In June

2009, Our first 7600m CT80 coiled tubing with O.D. 31.8 mm WT. 3.18mm has been put in use which indicates China

becomes the second country which can make industrialized production of coiled tubing after America.

After overall inspection of National Petroleum Tubular Quality Supervision and Inspection Center and field application, all

results show that the performance of coiled tubing we supplied fully meet the requirements of API 5C7 and API 5ST,not

only prossess good corrosion resistance and fatigue test results is superior to similar imported coiled tubing, but also its

comprehensive performance reaches the level of abroad similar products, and can completely replace imported coiled tubing

to meet the demands of petroleum industry in China.

4. Quality Assurance

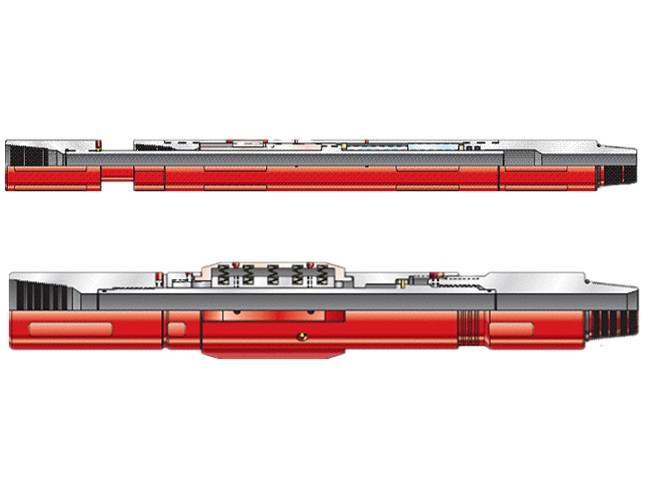

In order to assure product quality and supply to the user’s satisfaction, coiled tubing production line adopts advanced control

technology to strengthen production process control with world-class NDT equiments such as Ultrasonic inspection, X-ray

inspection and eletromagnetic etc, and also built perfect quality assurance asystem. Meanwhile, advanced inspection methods

are used to control key process as priority such as butt welding, HFW welding and heat treatment etc, and also six of 100%

quality control inspections are carried out to assure the best products quality.

100% magnetic flux leakage inspection of raw materials.

100% X-ray, UT,hardness and magnetic particle inspection on strip butt welds

100% laser detection on pipe diameter

100% weld eddy current inspection

100% full body magnetic flux leakage inspection

100% hydrostatic test