Topics > Wellhead & Environment

Drilling Waste Management

03/11/2015

Drilling Waste Management

Drilling waste management has put forward higher requirements with the constant improvement of the environmental protection requirement. Drilling waste purification system can not only be very good to solve the environmental problems, but also can do recycling to the waste of the solid control system. While drilling cutting management system maximize retains the useful mud, and it concentrated solidify after processing of drilling cuttings. That helps to reduce the destruction of the environment in oil filed working.

Oilfield environmental drilling waste management system usually contains drying shaker, screw pump, vertical cutting dryer, screw conveyor, etc those can be used for the mud dry processing such as solids control equipment

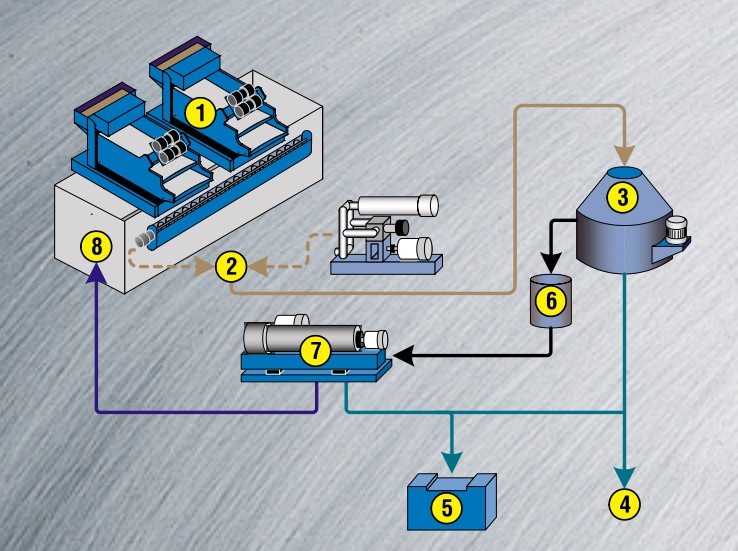

Drilling Waste Management Process:

1. Vertical cutting dryer

Vertical cutting dryer is mainly used in waste mud treatment for environmental protection. KINGWELL Dryer can effectively recycle

oils from the cuttings, which can effectively achieve curing transport and meet the requirements of environmental protection. KINGWELL vertical cutting dryer’s capacity is 40-50 tons per hour, and usually the oil content is lower than 3% after processing, which means KINGWELL vertical cutting dryer can conform to the requirements of the typical 6%. KINGWELL vertical cutting dryer can be used for various types of drilling mud and it is very effective to dry oil-based and compound base drilling cuttings mud.

| Model | KWVC-1000 |

| Max. Diameter Of Drum | 950mm |

| Rotation Speed | 820r/min |

| G-Force | 360 |

| Max.Capacity | 60T/h |

| Oil On Cuttings (OOC) | ≤5% |

| Main Motor Power | 55kW(75HP) |

| Screen Openning | 0.015”,0.020” |

| Ex-Mark | ExdⅡBT4/ ExdⅡCT3 / ATEX |

| Power | 380V/50Hz or 460V/60Hz/td> |

| Dimensions(L×W×H) | 3820mm×3360mm×5900mm |

| Weight | 8700kg |

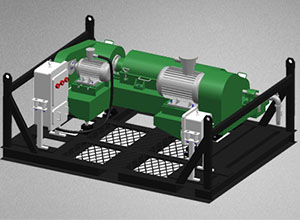

2. Decanter centrifuge

Decanter centrifuge is used to separate suspended solids ≥2μm in diameter and treat the drilling mud and fluids. It is especially effective when used in oilfield service industry, industrial service industry and especially in environmentally sensitive areas. This type of centrifuge is high in recovery rate, effective in solid control and remarkable in the reduction of cost spent on drilling mud resupplying and management. It is a very sophisticated dynamic balancing machine, able to operate stably with the whirling speed ranging from 0 to 3900 and generate centrifugal force of 3000G.

Technical Parameter

| Model | KWD450 | KWD355 | KWI355 | ||

| Fixed Speed | VFD | Fixed Speed | VFD | Fixed Speed | |

| Bowl Diameter(mm)/(in) | 450/18 | 450/18 | 355/14 | 355/14 | 355/14 |

| Bowl Length(mm)/(in) | 1000 / 39 | 1000 / 39 | 1257 / 49 | 1257 / 49 | 1422 / 56 |

| Max. Bowl Speed(RPM) | 3200 | 3900 | 3900 | 3900 | 3900 |

| Typical Bowl Speed(RPM) | 1700 & 2200 | ~3300 | 2000 & 3200 | ~3200 | 2000 & 3200(60Hz) |

| G-Force | 728 & 1215 | ~2745 | 794/2032 | 794/2032 | 794/2032(60Hz) |

| Max Capacity(m³/h) | 45m³/h | 45m³/h | 35m³/h | 35m³/h | 35m³/h |

| Separation point (μm) | 4~7 | 2~7 | 2~7 | 2~7 | 2~7 |

| Main Motor(kW) | 30 | 30 | 30 | 30 | 37 |

| Back Drive Motor(kW) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Type of Gearbox | planery1:57 | planery1:57 | planery1:57 | planery1:57 | planery1:57 |

| Dimension: L×W×H(mm)/(in) |

2900×2200×1285 /114x87x51 |

2900×2200×1285 /114x87x51 |

2960×2200×1470 /117x87x58 |

2960×2200×1350 /117x87x53 |

3350×2200×1285 /132x87x51 |

| Weight(kg) | 2870 | 3450 | 2940 | 3520 | 3310 |

| Power | 460V/60Hz or 380V/50Hz or Customized | ||||

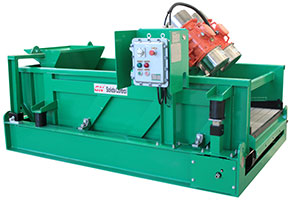

3. Drying Shaker

Drying shaker is one of the KINGWELL’s new shale shakers combining with the international market demand which can meet the needs of environmental protection. Drying shaker is the first phase of solid control equipment. Drying shaker makes the whole tail drilling processing sustained and effective by drying, screening and purifying drilling cutting waste. And it is the perfect match with vertical cutting dryer.

Technical Parameter

| Model | KWLS584-D |

| Motion | Linear Motion |

| Motor Power kW/HP | 2×1.86kW(2×2.5HP)(Martin) |

| Vibrating Strength | 7.3(6.8~7.8) |

| Shaker Screen m²/ ft2 | 2.7/29 |

| Deck Adjustment | -1~+5 |

| screen type | Frame/Pre-tensioned |

| Screen Dimension mm/in | 585×1165 / 23×46 |

| screen quantity | 4 |

| Noise(dB) | <85 |

| Weir Height mm/in | 1171/46 |

| Dimension mm/in | 2752×1892×1762/108×74×69 |

| Weight kg/lbs | 1590/3506 |

| Remark | Collecting Box Volume:1.5m³ |

4. Screw conveyor

Screw Conveyor has horizontal, diagonal and combination form. it can be used with other transportation equipment. And it works through the combined transport, separate transportation, mixing, blending, dehydration, compound, unloading and stacking, etc. the whole drilling processing. Screw conveyor is used to deal with the waste drilling fluid and cuttings transportation.

| Model | KWLS305 | KWLS355 | ||||

| Diameter (mm)/(in) | 305 / 12 | 355 / 14 | ||||

| Change speed through pulleys (RPM) | 40/60 | 40/60 | ||||

| Change speed through handwheel(RPM) | 40~100 | 40~100 | ||||

| Max. Capacity(T/h) | 40 | 50 | ||||

| Length (m)/(ft) | 3.66 / 12 | 7.32 / 24 | 10.97 / 36 | 3.66 / 12 | 7.32 / 24 | 7.32 / 24 |

| Motor Power (kW) | 5.5 | 7.5 | 11 | 5.5 | 7.5 | 11 |

| Dimensions (handwheel) (mm)/(in) |

4940×450×800 /194×18×31 |

8600×450×800 /339×18×31 |

12260×450×800 /483×18×31 |

12260×450×800 /483×18×31 |

8600×510×800 /339×20×31 |

12260×510×800 /483×20×31 |

| Dimensions (pulleys)(mm)/(in) |

4340×450×1300 /171×18×51 |

8000×450×1300 315×18×51 |

11660×450×1300 /459×18×51 |

4340×510×1300 171×20×51 |

8000×510×1300 /315×20×51 |

11660×510×1300 /459×2 |

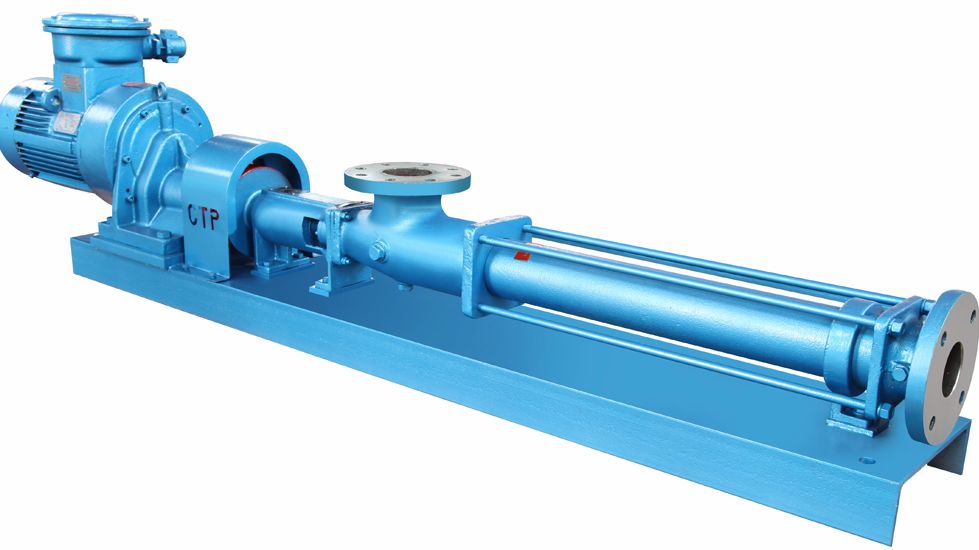

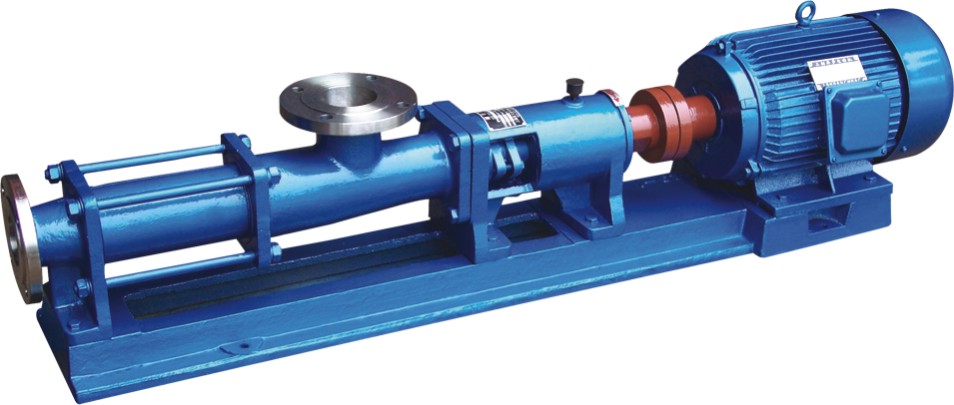

5. Screw pump

It is a slurry transportation equipment in the processing of drilling cuttings tail rotor. The features are less components, compact structure, small volume, simple maintenance, and easy installation for pump rotor and stator which are vulnerable parts.

Technical Parameter

| Model | Flow | Pressure | Max Speed | Motor | Inlet | Outlet | Max solids |

| KWSWP-40 | 12m3/h/53GPM | 0.6MPA | 960RPM | 4kw/5.5HP | 80mm/3in | 65mm/21/2in | 3.8 |

| KWSWP-50 | 14m3/h/62GPM | 0.6MPA | 720RPM | 5.5kw/7.5HP | 100mm/4in | 80mm/3in | 5.0 |

| KWSWP-60 | 22m3/h/97GPM | 0.6MPA | 720RPM | 11kw/15HP | 120mm/5in | 100mm/4in | 6.0 |

| KWSWP-70 | 40m3/h/76GPM | 0.6MPA | 720RPM | 11kw/15HP | 150mm/6in | 125mm/5in | 8.0 |

| KWSWP-85 | 56m3/h/246GPM | 0.6MPA | 630RPM | 15kw/20HP | 150mm/6in | 150mm/6in | 10.0 |

Products

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker