Topics > Wellhead & Environment

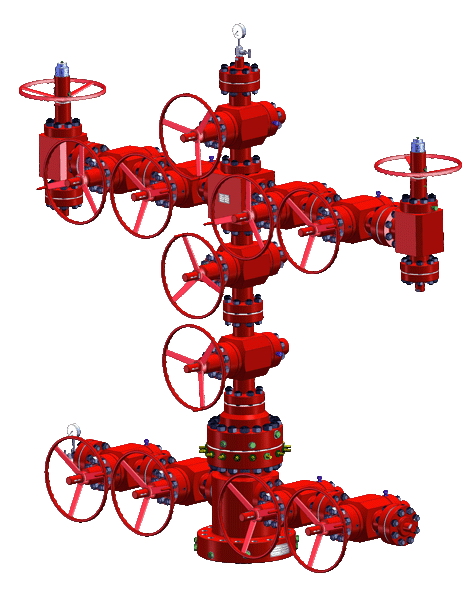

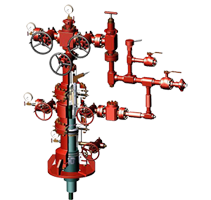

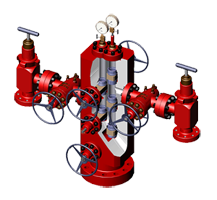

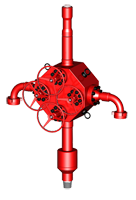

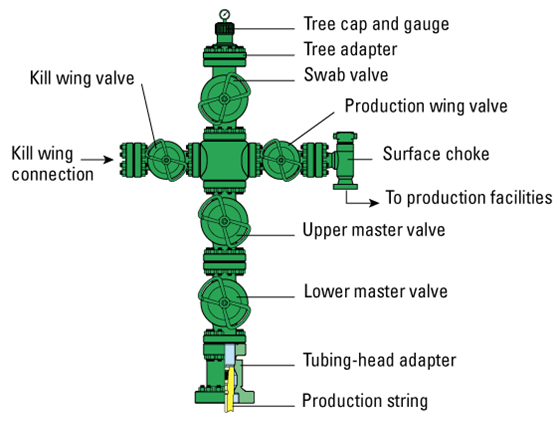

Christmas Tree

03/11/2015

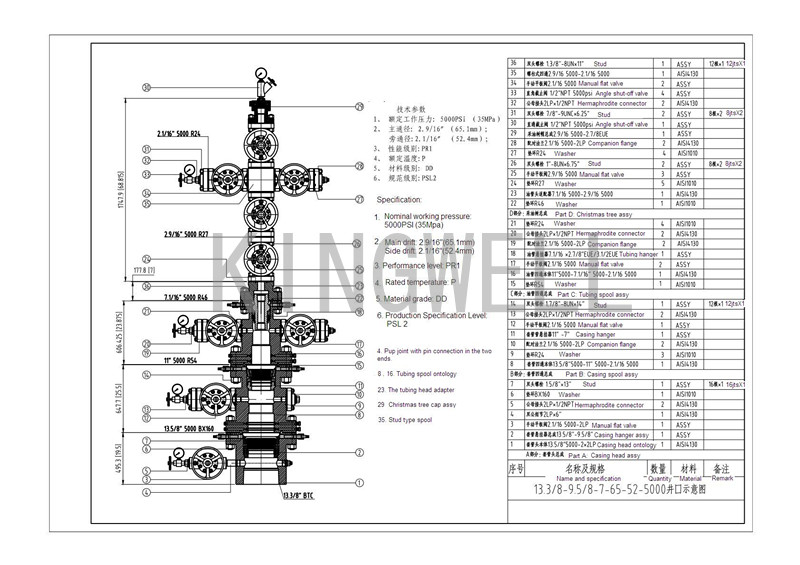

Dual Tubing Christmas Tree Well Test Equipment

Thread type casing head housing Weld type casing head housing Slip type casing head housing

Products

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker