Products > Drilling Equipment

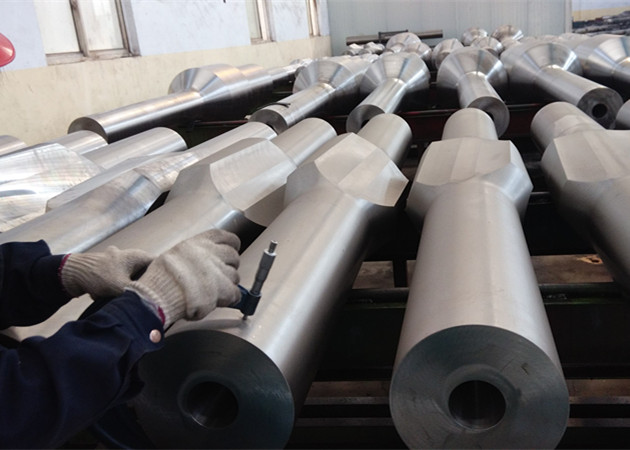

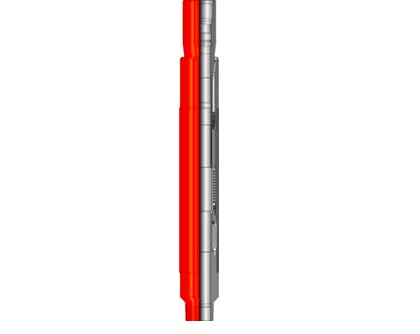

KINGWELL Stabilizer Technical Data:

|

Bit Size (in) |

Working OD (mm) |

End OD of body(mm) |

ID (mm) |

Length (mm) |

Thread code on both ends | |||

| Drill string type | Near bit type | |||||||

| Top | Down | Top | Down | |||||

| 6 | 152.2 | 121 | 51 | 1200 | NC38 | 3 1/2 REG | ||

| 6 1/4 | 158.7 | |||||||

| 6 1/2 | 165.1 | |||||||

| 7 1/2 | 190.5 | 159 | 57 | 1600 | NC46 | 4 1/2 REG | ||

| 7 7/8 | 200 | |||||||

| 8 3/8 | 212.7 |

159 165 |

71 |

1600 1800 |

NC46 NC50 |

|||

| 8 1/2 | 215.2 |

159 165 178 |

||||||

| 8 3/4 | 222.2 | |||||||

| 9 1/2 | 241.3 |

178 197 |

1600 | NC50 | NC50 | NC50 | ||

| 9 5/8 | 244.5 | 1800 | 6 5/8 REG | |||||

| 9 7/8 | 250.8 | |||||||

| 12 1/4 | 311.2 |

203 209 |

76 | 1800 |

NC56 6 5/8 REG |

NC56 6 5/8 REG |

NC56 6 5/8 REG |

6 5/8 REG |

| 16 | 406 |

229 241.3 |

2000 2200 |

NC61 7 5/8 REG |

NC61 7 5/8 REG |

NC61 7 5/8 REG |

NC61 7 5/8 REG |

|

| 17 1/2 | 444.5 | |||||||

| 24 | 609.6 | |||||||

| 26 | 660.4 | |||||||

| 28 | 711.2 | |||||||

| Note: Stabilizer can be made according to customer's special requirement. | ||||||||

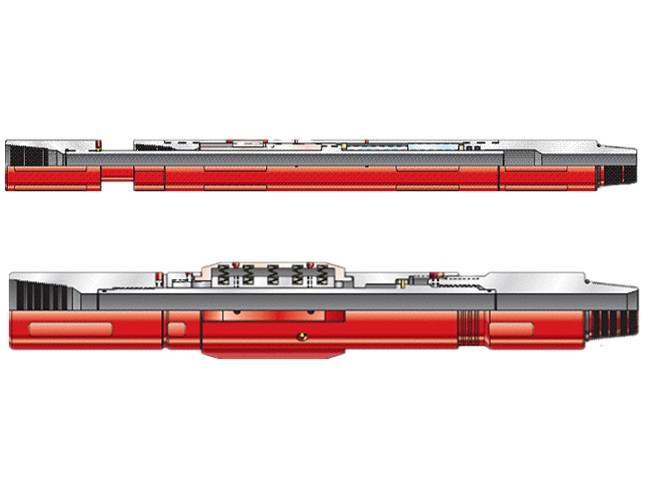

Non-magnetic Drill stabilizer technological regulation

1.Scope

This regulation applies for the production,inspection and marketing of non-magnetic drill stabilizer from KINGWELL.

This regulation includes technological requirements of non-magnetic drill stabilizer, test method, signal ,package, test certificate and quality control information.

This regulation applies to the latest edition of API Spec 7 ,if there are conflicts, should take API Spec 7 shall prevail.

2.Technological requirements

2.1 Chemical composition

sheet 1: Chemical composition(%)

| C | Si | Mn | Cr | Ni | Mo | N | P | S | Al | Cu | Nb | |

|

≤ 0.08 |

≤ 1.0 |

18.0 - 22.0 |

13.0 - 17.0 |

1.0 - 3.0 |

0.4 - 0.75 |

0.28 - 0.46 |

≤ 0.03 |

≤ 0.01 |

≤ 0.025 |

≤ 0.20 |

≤ 0.10 |

|

| Tolerance | ±0.01 | ±0.05 | ±0.15 | ±0.15 | ±0.03 | ±0.03 | ±0.03 | ±0.005 | ±0.005 |

2.21Mechanical property should be up to sheet 2.

Sheet 2 mechanical property

|

Yield Strength Rt(Mpa) |

Tensile Strength Rm(Mpa) |

Elongation A(%) |

Sharp V Impact Akv(J) |

Hardness Brinell (HB) |

| ≥758 | ≥827 | ≥18 | ≥75(longitudinal) | ≥285 |

The relative permeability for each drill stabilizer should be no more than 1.010 µr and the maximum deviation of uniform magnetic field should be no more than±0.05 µT. Inspection should use a magnetoscope and the probe for difference of magnetic fields. Magnetometer connected with the probe should be posited the axial direction of non-drill stabilizer and the difference of magnetic fields showed on the recording papertape should be a part of stabilizer inspection certificate, that's magnetic field gradient results.

2.23 Decay resistance

Each non-magnetic drill stabilizer should pass the current edition of ASTM A282 E method of corrosion test.

2.24 Straightness accuracy

The maximum straightness for each non-drill stabilizer is 0.52mm/m.

2.25 Axiality

The maximum deviation for all the diameters should be no more than 1mm.

2.26 Difference in wall thickness

The full range wall thickness difference for each non-magnetic stabilizer should be less than or equal to nominal thickness 12%, or less than or equal to 4.78mm, smaller was be preferred.

2.27 Surface

The surface should be smooth and the surface quality defects burnish depth should comply with the regulation of API SPEC 7-1, inner hole should carry on the cold roller processing.

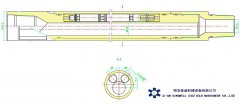

2.28 Size

The sizes of stabilizer must be complied with relevant constracts. The OD,ID and varios size must be according to the drawing.

2.29 Ultrasonic Test

Ultrasonic Test must be complied with the regulation of ASTM A388.

3.Test method and regulations

3.1 Mechanical Property

3.11

Both of the tensile specimen and impact specimen should be sampled longitudinally at any end of the forging,It should be 25.4mm away from the surface or in the center of the wall thickness, smaller will be preferred. It should be carried out in accordance with the column specimen of 0.2% conditioned yield point in ASTM A370. The impact specimen should be adopt the 10mm×10mm×55mm charpy V specimen, and the test temperature is 20℃±5℃.

3.12

The hardness test should be complied with the requirements of ASTM A370.

Surface Hardness: Choose two points separately from work part ,two ends,cant and do test.

Subcutaneous quadrant hardness: Do corss-shaped test at two ends of stabilizer, which posited subcutaneous 1.5",1" and each quadrant three value measurement.

3.13

The supplier chooses two stabilizers and leaves 150mm sample length at any end for the buyer to get a sample of 30mm×30mm×150mm.

3.2 Non-magnetic Test

Each non-magnetic drill stabilizer should be carried on relative permeability test,the test method should be noted on the certificates.

3.3 Intergranular Corrosion Inspection

Intergranular corrosion inspection must be complied with ASTM A262 E. Specimen sampling locates the axial from inner hole within 12.7 mm

3.4 Straightness measurement

The offset between the centre line of the two ends of stabilizer and tube body.

3.5 Wall Thickness Test

With Ultrasonic thickness gage do wall thickness test on the full range of non-magnetic drill stabilizer.

3.6 Ultrasonic Test

Each non-magnetic drill stabilizer should be carried on frull range Ultrasonic Test as per API SPEC 7-1.

3.7 Inner holes of each non-magnetic drill stabilizer should carry on the cold roller processing.

4. Signal

Producer signal,Furnace number and Serial number should be marked on the end of each non-magnetic drill stabilizer.

5.Package

No oil, no paint ,no wrap on surface of non-magnetic drill stabilizer.

Non-magnetic drill stabilizers will be tighten on the steel shelf.

6.Inspection Certificates and Quality control information

Inspection Certificate should include product name,furnace number,size,wall thickness difference test results,chemical composition,mechanical property,relative permeability test results, magnetic field gradient results, Intergranular Corrosion Inspection results,Ultrasonic Test results, surface quality.

-----------

Products

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve