Products > Packers

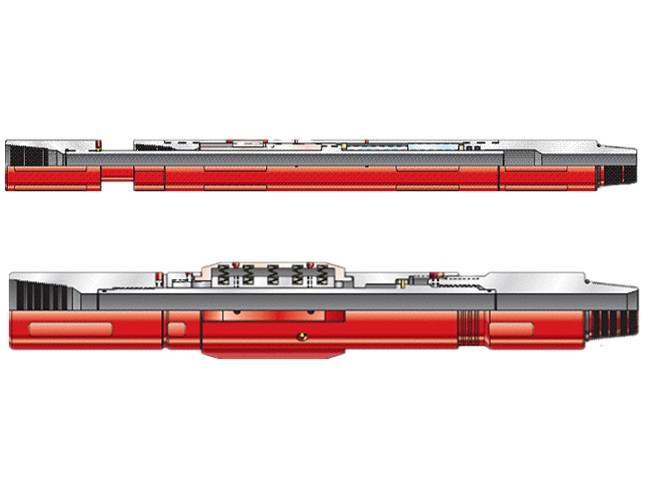

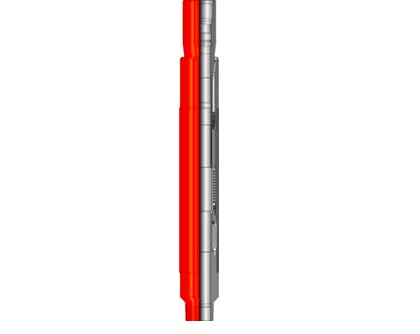

The swellable packer isolation system is the safer and simpler zonal isolation. The technology is based on the swelling properties of the rubber element reacting with well-bore fluids, drilling mud, or completion fluids and can swell up to more than twice their run-in volume, sealing the annulus in any open or cased holes.

Installation

The swellable packer is a joint of casing with a chemically bonded elastomer that swells when exposed to oil creating a lasing seal. No hydraulic pressure or pipe manipulation is required to activate the swellable packers, making the installation process very simple and straight forward. The simplicity of the system saves rig time and the rist of running small diameter inner strings and complicated pressure actuation systems. The lack of value systems and potential leak paths also makes swell packers a more robust long term solution.

Features

-No moving parts to malfunction

-Conforms to irregular shaped bore holes

-Provide seal lengths from 1 ft – 30 ft

-Up to 200% useable volume expansion

-Self – healing

Benefits

-Reduce well cost and rig time

-Enhance operational flexibility by enabling a higher pressure differential

-Long term sealing integrity

-Lower risk involved in installation

-No running tools required for deployment or activation

-Provide long term annulus isolation

-Reliability through simplicity

Applications

-Open and cased hole isolations

-Gravel-pack assemblies

-Straddle assemblies

-Water/gas shut-off

-Reservoir compartmentalization

Bonded to pipe tools technical specifications

| BONDED TO PIPE TOOLS TECHNICAL SPECIFICATIONS | |

| Operating Condition | Specifications |

| Run in hole fluid: oil based mud | Design to suit applications |

| Run in hole fluid: water based mud | All fluid systems |

| Temperature range | 30-390 (0-200) |

| Reservoir fluid: liquid hydrocarbon | Swelling rate is a function of fluid viscosity |

| Reservoir fluid: oil with high water cut | Swells in traces of hydrocarbon fluid |

| Reservoir fluid: water | Does not swell in water |

| Reservoir fluid: gas condensate | Will swell in the presence of any concentration of hydrocarbons. The element must be set using a liquid phase hudrocarbon. The packer is stable after set even if surrounding fluid changes to pure water or gas. |

| Differtial pressure capacity | Up to 15000 psi (1032 bar) |

| Time to set | Varies based on designs and well conditions |

| Chemical resistance | Common oilfield chemicals |

| Basepipe tensile/Burst/Collapse/Metallurgy | Can be built on any oilfield tubulars |

Products

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve