Products > Rig Parts

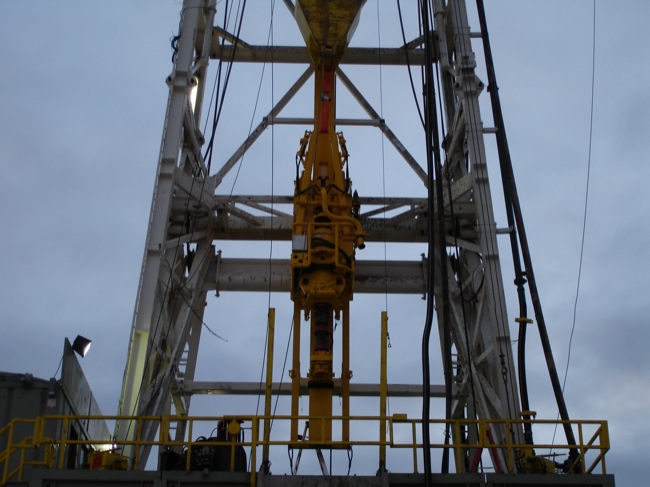

Top Drive System is a new-style drilling system, which is used to instead of the rotary table. It is integrated with mechanical, electrical and hydraulic technology and has advanced automation level. It’s called a great revolution in drilling equipment and also gives the direction for drilling equipment development in 21st century. Top Drive System has been the standard equipment in the international drilling industry and is suitable to be used in cluster directional well, high-inclination well and horizontal well, especially deep well and ultra deep well.

Direct Top Drive

1. Eliminate mechanical transmission mechanism; main shaft driven directly by motor.

2. Bearing is grease lubricated, without gear lubrication oil and cooling and filtering system, reducing sealing mechanism and easy for maintenance.

3. Modularized in design, structure is simple hence less fault points.

4. Direct motor drive provides higher working torque in a short time reducing drive energy loss.

5. More effective cooling and radiation of complete machine (arranged with high power blower and multiple air ducts.)

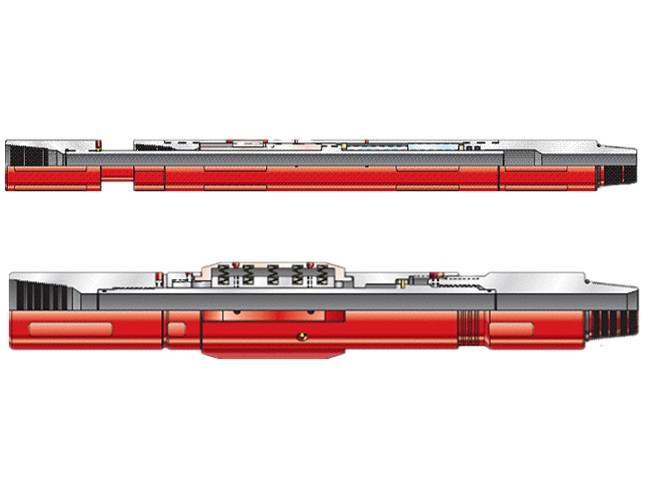

Mechanical Top Drive

1.Top drive device adopts heavy duty AC motor and is driven by AC variable frequency technology.

2. Top drive device adopts heavy load thrust bearing and special structure so that it resists longitudinal vibration of drilling string.

3. The tilting mechanism of pipe handling device can tilt forward, backward and rotate 360°, so that the main shaft will be closer to the derrick floor when it grabs the drilling stem and drills for better availability of drilling string.

4.The backup tong of pipe handling device has a large range of pipe handing, the inner blowout preventer control mechanism does not rotate with the elevator links,

5.Confronting complicate sections while tripping, the top drive at any height can connect drill pipe for drilling fluid circulation and reaming.

6. Stepless speed control and make-up/break-out torque control can be realized to meet the requirement of drilling process with high accuracy.

7. Top hydraulic kelly cock is equipped for closing and opening of inner blowout preventer (IBOP) at any height so as to increase security of well control.

8. Multiple protection mechanisms offer safety and reliability in working.

9. Independent diesel generator set is optional on-demand to supply power to top drive.

KINGWELL Top Drive Technical Data:

| Drive mode | Direct drive by AC variable frequency motor | |||

| Model | DQ225DBZ | DQ450DBZ | DQ675DBZ | DQ900DBZ |

| Maximum load (API8C) | 2250kN | 4500kN | 6750kN | 9000kN |

| Rotation speed range | 0-220 r/min | 0-220 r/min | 0-220 r/min | 0-220 r/min |

| Working torque | 25000 N.m | 45000 N.m | 70000 N.m | 90000 N.m |

| Maximum make-up/break-out torque | 45000 N.m | 75000 N.m | 125000 N.m | 135000 N.m |

| Braking torque | 35000 N.m | 50000 N.m | 70000 N.m | 90000 N.m |

| Motor power rating | 288kW | 580kW | 900 kW | 1130 kW |

| Holding range of backup tong (diameter) | 86-197mm | 86-216mm | 86-216mm | 86-250mm |

| Working pressure of hydraulic system | 16 MPa | 16 MPa | 16 MPa | 16 MPa |

| Nominal working pressure of central tube | 35 MPa | 35 MPa | 52 MPa | 52 MPa |

| Top drive weight | 12.3 T | 15.85 T | 18.5 T | 20.1 T |

| Top drive outline (length x width x height) | 5300×1990 ×1850(mm) | 5700×2180 ×2090(mm) | 6700×2720 ×2370(mm) | 7100×2720 ×2370 |

Products

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve