Tubing Spool

KINGWELL Tubing Spool Features & Benefits

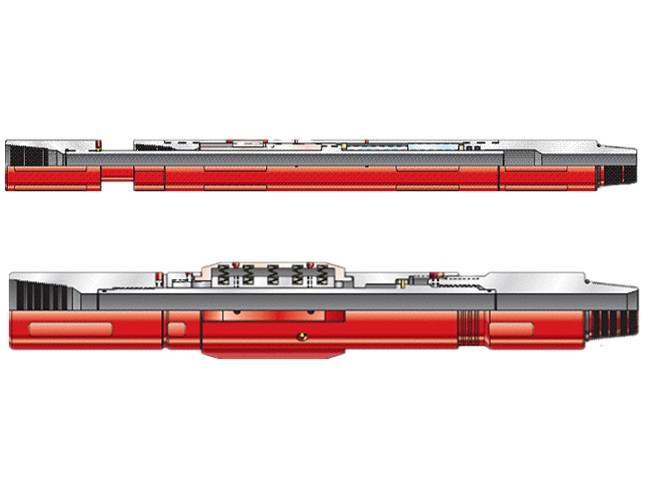

The tubing spool is the last spool installed before the well is completed. The tubing spool differs from the intermediate spool in one way: it has a profile for accepting a solid body-tubing hanger with a lockdown feature located around the top flange. The lockdown feature ensures that the tubing hanger cannot move because of pressure or temperature. The flange sizes vary in accordance with pressure requirements. When the well is completed, the tree is installed on top of the tubing head with a tubing head adapter.

Tubing Head &tubing spool are a straight bore bowl with 45° landing shoulder design which avoids damage to sealing areas by drilling tools, and provides wedging of the tubing hangers, bowl protectors and test plugs. the secondary seal for the last casing pipe can be an integrated "OO" seal type or the plastic injection type, but also accepts reducer bushings "4-O" and "PE" (Pressure Energized).The upper flange is supplied with lockdown screws for packoff tubing hanger retention. The lower flange includes a grease fitting and orifice for testing of the secondary seal.

Feature:

1. Versatile straight-bore design,uses a 45° landing shoulder can safety support maximum loads.

2. Bodies can be made from materials suitable for many severe service environments.

3. Two different types of outlets: line pipe outlets and flanged padded (studded) outlets.

KINGWELL Tubing Spool Techincal Data:

Working Pressure:2000psi~20000psi

Temperature Level:KU

Material Class:AA、BB、CC、DD、EE、FF、HH

Product Specification Level:PSL1~PSL4

Product Performance Level:PR1~2

Medium: oil, natural gas, slurry, gas containing H 2 S and CO 2

Casing Spool

KINGWELL Casing Spool Features & Benefits

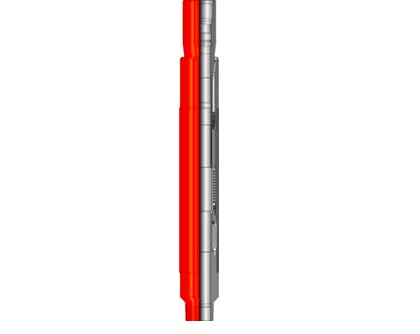

The casing spool has a top bowl to accommodate the casing hanger. The spool also has a bottom bowl with a pack off seal and a flange or lamp hub for mounting it on top of a casing head or previous spool. Outlets are provided for annular access. Multiple casing spools may be stacked to hang intermediate and production casing strings.

Casing spools are also straight bore bowl design. Bottom preparation can be either for P-seals or X-bushing types secondary seals, outlets are normally 2 1/16” studded with 1 1/2” VR plug profile.

Casing spools provide interchangeability of casing hangers. If a bowl protector is required during the drilling process, using a C-22 SOW casing head, including lock down screws in the upper flange would be recommended. Alternatively, a hold down flange with lock screws can be used.

Features

• Versatile straight-bore design,uses a 45° landing shoulder;

• 3 different types of outlets: Line pipe, Flanged (Studded) Extended flanged outlets.

• Allows use of lock screws to retain hanger.

• Has a additional lock screws for Bowl protection..

• Accepts a wide variety of slip and mandrel casing hangers.

• Multiple bottom sealing type, such as: PE/BG bottom,OO bottom and double "P" seal bottom.

KINGWELL Casing Spool Techincal Data:

working pressure:2000psi~20000psi

Temperature level:KU

Material Class:AA、BB、CC、DD、EE、FF、HH

Product Specification Level:PSL1~PSL4

Product Performance Level:PR1~2

Medium: oil, natural gas, slurry, gas containing H 2 S and CO 2