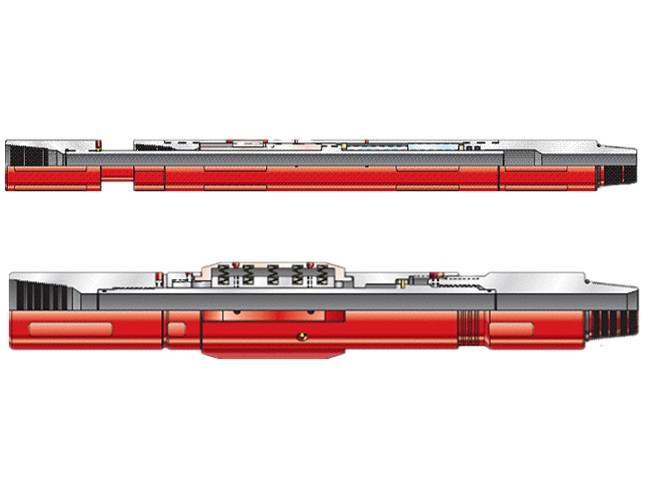

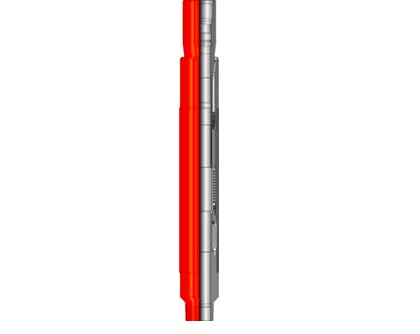

The storm vavle is a combination Back Pressure Vavle and Safety Joint that is run above a KWWELL Storm Packer, in order to provide well control protection during a temporary abandonment of the well, without having to pull the drill pipe. The Storm Vavle allows the pxckers to be set and then permit disconnection and retrieval of the drill pipe and the upper sub of the vavle, while at the same time automatically closing the Storm Vavle, isolating the drill pipe below the Storm Packer.

Can be easily runned by rotating the tubing string which can open and close the vavle.

In emergency situation, the plug can open drill pipe passage.

It is designed to be used with right hand set compression type packers only.

|

SPECIFICATIONS |

|

Part NO |

Casing |

Gage Ring

NO. |

Tool max.

O.D |

Tool min

I.D |

Threads Box up/pin down |

|

605-103 |

7 5/8" |

054KW-5605-144 |

6.125 |

1.750 |

4 1/2-I.F. |

|

|

8 5/8" |

054KW-5605-145 |

7.000 |

|

|

|

|

9 5/8" |

054KW-5605-146 |

8.000 |

|

|

|

|

13 3/8" |

054KW-5605-147 |

11.750 |

|

|

|

605-104 |

7" |

054KW-5605-143 |

5.500 |

1.750 |

3 1/2-I.F. |

|

|

7 5/8" |

054KW-5605-144 |

6.125 |

|

|

|

|

8 5/8" |

054KW-5605-145 |

7.000 |

|

|

|

|

9 5/8" |

054KW-5605-146 |

8.000 |

|

|

|

|

13 3/8" |

054-5605-147 |

11.750 |

|

|

|

605-105 |

5 1/2" |

NA |

3.720 |

1.000 |

2 7/8’ EU.

8RD |

Cased Hole Drill stem testing tools(DST) through the list.

Drill Stem testing tools string(DST tools)

7" Fullbore safety joint RTTS Drill stem testing tools(DST)

Drill stem testing tools

Drill stem testing tools

Sub surface safety valve parts TOP-SSSV-02

DST tools gauge carrier

Hydro spring tester MFE

5" Hydrospring tester (MFE)

Hollow plug Impact reversing sub

VR Safety Joint open hole DST

5" VR Safety joint open hole

5" VR safety joint for open hole DST in stock

Internal Pressure operated circulating valve

Internal Pressure operated Circulating valve IPO

Super Safety Valve DST

7" Radial Shock Absorber in stock

DST Radial Shock Absorber

5" Sleeve type drain valve in stock

3 7/8" sleeve type drain valve

Sleeve Type Drain Valve

5" Sleeve type drain valve in stock

Tubing String Testing Valve

3 7/8" Gauge carrier drill stem testing

5" x 15K psi RD Sampler drill stem testing

3 7/8" Rupture Disk Sampler RD Sampler drill stem testing

Full Bore Retrievable Packer

Drill stem testing casing packer 7", RTTS

DST OMNI circulating valve

APR full bore retrievable packer

Champ IV Packer DST

Full bore retrievable packer TOP-RTTS packer-01

13 5/8" Full bore retrievable packer RTTS packer

7" Full bore retrievable packer in stock

7" Full bore retrievable packer in stock

9 5/8" Full bore retrievable packer in stock

5" OMNI Circulating valve in stock

9 5/8" RTTS packer Drill stem testing

5" OMNI Circulating valve in stock

5 1/2"Full bore retrievable packer drill stem testing

Rupture Disk Safety Circulating Valve

Full bore retrievable circulating valve

7" RTTS circulating valve

5" Rupture Disk RD Circulating Valve

FUL-FLO Pressure Controlled Multi-circulating Valve

5 1/2" Full bore retrievable circulating valve drill stem testing

3 7/8" OMNI Valve Repetitious circulating valve

13 3/8" full bore retrievable safety joint drill stem testing

3 7/8" Rupture Disk RD Circulating valve drill stem testing

3 7/8" Hydraulic Jar Big John Jar BJ Jar drill stem testing

5" x 15k psi RD Safety Circulating Valve drill stem testing

3 7/8" Rupture Disk Tubing string testing valve RD TST valve drill stem testing

3 7/8" Tubing string testing valve drill stem testing

3 7/8" select tester valve drill stem testing

APR Drill stem testing tools select tester valve

LPR-N Tester Valve DST

5" Rupture disk RD sampler in stock

5" Select tester valve in stock

5" Tubing string testing valve TST valve

5" Rupture disk sampler stock

Sub Surface Safety valve

Rupture Disk Bypass Pressure Test Valve

DST Select tester valve

Tubing string testing valve TST valve

hydraulic jar Bigjohn Jar

5" hydraulic jar Bigjohn Jar Stock

5" x 15K psi OMNI Valve drill stem testing tools

Full bore retrievable safety joint RTTS safety joint

5" Round Mandrel slip joint drill stem testing

3 7/8" Round Mandrel slip joint drill stem testing

5" Round mandrel slip joint

3 7/8" Round Mandrel Slip Joint in stock

Round Mandrel Slip Joint

-------

testing and

Quality control &operation training

We kindly offer the free operation training to clients who purchase Yuanheng product.

The training content varies to the different need of the customers. Generally speaking, our customer training mainly includes followings:

1 Contents and purpose:

1)Learn and master the use, working environment, working principles, structure, disassembly, maintenance, requirements of test and operations of the tools fixed in contract(No. GW101),

2)Basic requirement of designs of tool strings and of testing operation.

3)Brief introduction on the development of DST.

2 Intended effect:

1)Each trainee could describe working principles and structure of tools and could disassembly, maintain and test independently

2)Known well on the following points: check before use, cautions when using, operations on ground, process of deblocking and pulling up and ground working of disassembly and checking.

3)Aquire general ideas on basic requirement of designs of tool strings and of testing operation

4)Aquire general ideas on DST development.

3 Training effect test

After training, we will arrange theory and site operation test. The qualified trainees will acquire the qualification certificate issued by

Quality control of the raw material:

1)The selection of the raw material supplier:our raw materials mainly include alloy structural steel, stainless steel, non-ferrous metal alloy and high nickel alloy, etc, in the selection of the raw material suppliers, we would do the comprehensive assessment of the supplier strictly according to technical requirements .Most of our suppliers are the leading enterprises of the steel production in China , such as the DAYE SPECIAL STEEL CO., LTD , XI NING SPECIAL STEEL CO.,LTD etc. While the special alloy are usually purchased from abroad to ensure a higher mechanical properties.

2) The acceptance & Inspection of the raw material:

Ultrasonic flaw detection for every piece of the steel.

Chemical composition analysis, for every piece of the steel.

Mechanical performance test for every piece of the steel.

Only the above three items are qualified can the raw material be printed qualified logo and accepted as the qualified raw materials.

2、Quality control of the seals:

1) O Rings: 100% visual and dimensional inspection for every piece of the O-rings ,15% spot check for the size and hardness test of the o rings. As for the sealing and heat resistance properties of the o rings, we designed a special test device which is equipped with a heating insulation equipment that can simulate the downhole temperature and pressure. At present, our fluorine can keep a good performance in the condition of 210 ℃, and 105 Mpa work pressure (maximum pressure ever reached 146).

2) Back-up ring: 100% visual and dimensional inspection for every piece of the back-up ring, As for the test of the sealing and heat resistance, we design and manufacture the special test device, equipped with heating insulation equipment to stimulate the downhole temperature and pressure for acceptance. At present, our company's high pressure back-up seal can keep good sealing performance and deformed a little in the condition of 210 ℃, and 105Mpa work pressure (maximum pressure ever reached 146). It can be used for many times.

3. Quality control of the spring: Apart from the conventional test of the raw material and size of the different springs that used in the tools, we specially designed a test device that equipped with a heating preservation equipment to stimulate the downhole temperature and condition to test the spring performance.

4. Quality control of the spare parts processing:

1) Spare parts processing control:In strict accordance with the process and traceability requirements, a test, mark and record of dimension, geometric tolerance and for every piece and every procedure will be conduct.

2) Heat treatment quality control: We have two high temperature heat treatment furnaces that are mainly used for stainless steel and other special material heat treatment. For other materials, we entrust Baoji Petroleum Machinery Company Heat Treatment Plant to do the heat treatment. For the inspection of the heat treatment, we are equipped with the special inspection machine such as gantry hardness tester, digital universal tensile tester etc.;

5. Quality control of the tool assembly and testing process

1) Test equipment: in addition to the conventional hydraulic test pump, tensile testing machine, we also have a pressure sensor and data acquisition system which can accurate and clear record each step of the test.

2) Technical documents: We have a test acceptance list for every tool test that clearly guides the each step of the test.

3) Assembly test: A special inspector will supervise the whole assembly process.