Products > Casing Scraper

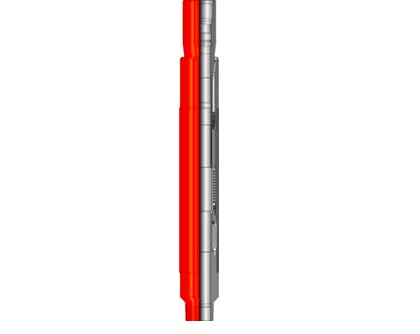

The Casing Scraper is used to remove cement scale, mud, mill scale, rust, paraffin, perforation burrs and other substances from the inside walls of casing. This operation produces a smooth inside casing diameter that will assist in a successful down hole operation such as setting packers, bridge plugs, etc.

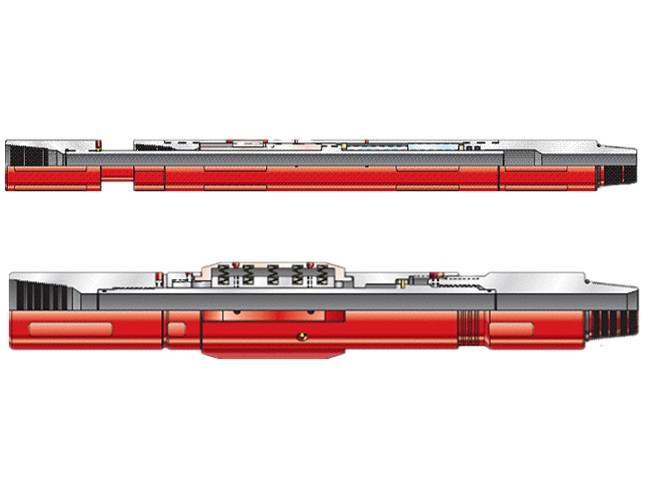

The sharp 360Casing Scraper is composed of a rugged one-piece mandrel design with a two-piece split

ring retained by four screws in the center. Blades are spring loaded and are designed to scrape a full range of com- mon casing weights with only one size

of blade for each different casing O.D.

The blades are precision cast from high- quality wear-resistant tool steel. They are very tough, but not brittle. They tend to work-harden slightly in service, which prevents wear very effectively. The blades are designed to fit closely over the spring housing welded to the man- drel, so that lateral movement is kept to an absolute minimum.

Springs are made of corrosion resistant 302 stainless and are totally enclosed between the blade and spring housing. Accidental loss down hole is virtually impossible.

The mandrel is made from heat treated alloy steel and has a pin by box connec- tion. Both ends have a suitable fishing neck to allow fishing out of the well if required.

Operation

Thesharp 360Casing Scraper is usually run with the pin connection up. It can be run either way at the convenience of the operator. The scraping action of the blades is identical in either case.

The configuration of the blades is such that the area scraped by the top row is overlapped by the row on the bottom.

The tool is made up on the string, and usually a bit is installed on the bottom. The Scraper is run in and the scraping operation begun, rotating or spudding as desired.

When a blade encounters an abrupt obstruction, such as a perforation burr or a fragment of cement, it is held firmly in its close-fitting slot by the mandrel and two-piece retainer ring.

Very slight or very gradual changes in casing internal diameters are passed over without damage to the casing, since the blades move in or out adjusting itself to the irregularities. The blades are sim- ply held in contact with the clean surface of the casing without cutting the metal.

Maintenance

Good maintenance will prolong the life of the tool and prevent misruns. After each use, the tool should be completely disassembled and thoroughly cleaned. Any worn or damaged parts should be replaced as this time. See Disassembly and Assembly below.

Disassembly

1.Clamp the mandrel in a suitable vise, near one end.

2.Remove four (4) socket head screws from split ring.

3.Remove all blades and springs from tool.

4.Thoroughly clean all the parts, and examine each for wear or damage. Replace any badly worn or damaged parts.

Assembly

1.Clamp the mandrel in a vise near one end.

2.Insert springs into slots provided on mandrel and hold in place with thick grease.

3.Place one row of blades in position and using banding tool, compress blades against the mandrel.

4.Secure Band and remove banding tool.

5.Place second row of blades in position and using banding tool compress blades against the mandrel.

6.Install split ring between the blades and secure ring with four (4) socket head screws. Coat threads (blue).

7.Remove banding tool and steel band from first row of blades. Thesharp 360Casing Scraper is now ready for use.

- Robust, self-sprung, single piece scraper machined from a single billet of steel with multiple rows of overlapping teeth.

- The scrapers fits perfectly inside the casing and is strong enough to provide a strong scraping force to ensure 360-degree coverage, something that a spring-cushioned scraper cannot do.

- Two fluted Centralizer Rings provide centralization, bypass and protects the whole tool.

- Free rotating tool design with Internal Bearing Rings prevent drill pipe, tool or casing from wearing.

- It can be quickly assembled redressed on location with simple hand tools.

- No external bolts, clamps or fasteners that can come loose down hole.

- Robust assembly method with multiple back-ups.

There are other Series as well:

-RIGID Sharp-Razor™ Casing Scraper

-Sharp-Razor™(HWDT) Non-rotating Casing Scraper

-Super Unique Non-Rotating Scraper

-Hydraulic Casing Scraper

Technical specification:

| TYPE |

I.D. in (mm) |

Tool Joint Connection API |

Overall length ft-in (mm) |

I.D of suitable casing in(mm) |

| KW114 |

1 (25.4) |

2-3/8REG |

3' (906) |

3-13/16~4-3/32 (97.2~103.9) |

| KW127 |

1 (25.4) |

NC23 |

3'3" (1,000) |

4-1/4~4-9/16 (108.6~115.8) |

| KW140 |

1 (25.4) |

NC26 |

3'3" (1,000) |

4-5/8~4-15/16 (118.6~125.7) |

| KW178 |

1-3/16 (30.0) |

3-1/2REG |

3'8" (1,105) |

6~6-3/8 (154.8~161.7) |

| KW245 |

2-1/4 (57.0) |

4-1/2REG |

4'5" (1,340) |

8-1/2~8-7/8 (216.8~226.6) |

| GGQ340 |

3-1/2 (88.9) |

6-5/8REG |

4'11" (1,500) |

12-3/6~12-3/4 (315.3~323.0) |

Products

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve