Specifications:

1. OEM interchangeable

2. Competitive price

3. API standard and high quality

4. Longer working period

KINGWELL Mud Pump Liner Features & Benefits:

KINGWELL Bi-metal liners

1. Our liners can be used in various drilling operation conditions.

2. The bi-metal outer surface is made of premium carbon steel, the inner sleeve is made of wear-resistant high chrome cast iron and the surface hardness reaches HRC62.

3. The sleeve is manufactured to the bore tolerances specified by API to provide longer life by reducing gaps between the liner bore and piston. After the shell and sleeve are assembled, the I.D. of the liner is honed to a perfect circle and polished to a mirror finish. the dimension of the inner hole is precious and service life is up to 800 hours

KINGWELL Hy-Chrome Liner

1. In order to satisfy high pressure request and high wear-resistant, we promote the hy-chrome liner, it is also Bi-metal, but with extra chemical contents Mo, Ni, Cu, V in materials and the content for Cr is 26%-29%. The properties are highly improved.

2. Service life is up to 1400-1600 hours

3. Better wear –resistant than common bi-metal liners.

KINGWELL ceramic liner

1. Ceramic liner can be suitable for deeper oil reservoir, bad drilling geological structure environment, offshore oil and gas development.

2. The material of ceramic liners is the increased flexible zirconium ceramic.

3. It is wear resistance, high anti-corrosion, high temperature resistance, high pressure, high intensity and high hardness. The using time of liners is up to 6,000 hours.

4. Zirconium ceramic liners have better performance than alumina ceramic liners such as more toughness, longer service life, saving water lubrication, reducing wear of piston.

KINGWELL Hardened Steel Liner

1. Our hardened steel liner is made from premium seamless steel tube or premium forged steel.

2. The bore is carbonized and quenched, which can be up to Rockwell C scales hardness of 58 to 62.

3. Good yield strength, and wear characteristics.

KINGWELL Chrome Plated Liner

1. Made from premium forged stell with a chrome-plated bore.

2. Rockwell C Hardness is 58 to 62.

3. Durable

KINGWELL liners are interchangeable to OEM’s such as BOMCO, RG, HH, National, Emsco, Gardner Denver, Ideco and Oilwell

|

Bomco/RG/HH |

|

F-500 |

F-800 |

F-1000 |

F-1300 |

F-1600 |

|

F-1600HL |

F-1600L |

F-2200HL |

F-2200HL |

|

|

Russion |

|

8T-650 |

UNBT-600 |

UNBT-950 |

UNBT-1180L |

UNBT-950A |

|

UBT-400 |

BT-600 |

UB-590 |

UNB-600 |

|

8T310 |

8T650-01 |

|

|

National |

|

7-P-50 |

8-P-80 |

9-P-100 |

10-P-130 |

12-P-160 |

|

14-P-200 |

14-P-220 |

N-1000/1300 |

|

|

|

EMSCO |

|

F-350 |

F-500 |

F-650 |

F-800 |

F-1000 |

|

FB-1300 |

FB-1600 |

|

|

|

|

Gardner Denver |

|

PAH |

TEE |

PZ-7 |

PZ-8 |

PZ-9 |

|

PZ-10 |

PZ-11 |

|

|

|

|

IDECO |

|

T-500 |

T-800 |

T-1000 |

T-13000 |

T-1600 |

|

Oilwell |

|

A-350 |

A-560 |

A-600 |

A-850 |

A-1100 |

|

A-1400 |

A-1700 |

|

|

|

|

Others |

|

350-D |

350-DG |

500-DC |

700-HDL |

1000-HDL |

|

MAS1000 |

|

|

|

|

-----------------------

1. Triplex mud pump liner(Ceramics Cylinder Sleeve ):

product introduce and advantage

Our ceramic liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a ceramic inner sleeve. We provide Zirconia(ZrO3) Sleeves as wellas Alumina(Al2 O3.) sleeves., of which Zirconia exhibits better impact strength, higher hardness and be honed to finer surface finishes thanalumina.

Ceramic liners are currently thepremium liner offered today. Ceramic liners have been known to operate well overthe 7000-hour work. Due to the high hardness of the ceramic surface, they wearsubstantially less than other liner types. This translates into longer pistonoperating times. If the correct conditions are present, the cost per operatinghour can be much less than that of the other liner types

Size in inches: 4,4-1/2,5 5-1/2, 6,6-1/4, 6-1/2,6-3/4,7

Size in mm: 100,110,120,130,140,150,160,170,180

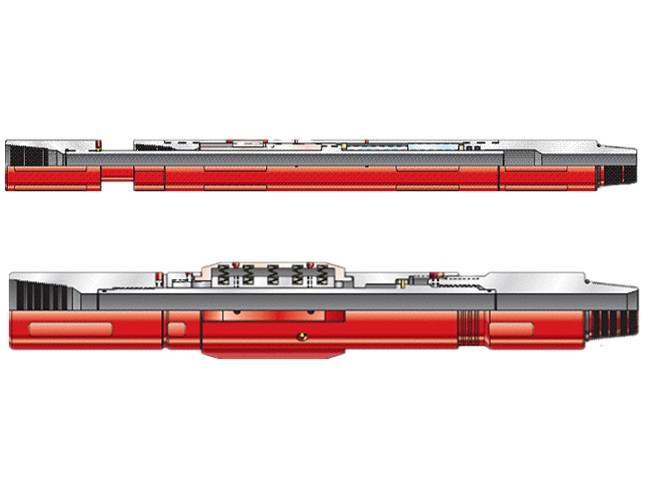

2. Introduction of Bi-metal Liner:

Heat Treated Bi-metal Liner for Mud Pump

Outer surface: premium carbon steel

Inner sleeve: high chrome

Hardness: HRC60~67

3. API Std. Mud Pump Liner for Oil Drilling:

A cylinder liner ( or cylinder sleeve) is a cylindrical part to be fitted into an engine block to form a cylinder. It is one of the most important functional parts to make up the interior of an engine. Our products after quenching technology for the surface and heat treating, the forged liner is with high intensity, strong tenacity and wearability. Main functions as belows:

(1) Formation of sliding surface:

The cylinder liner, serving as the inner wall of a cylinder, forms a sliding surface for the piston rings while retaining the lubricant within. The most important function of cylinder liners is the excellent characteristic as sliding surface and these four necessary points.1) Less wear on the cylinder liner itself2) Less wear on the partner piston ring 3) Less consumption of lubricant

(2) Heat transfer:

The cylinder liner receives combustion heat through the piston and piston rings and transmits the heat to the coolant.

(3) High temperature and high pressure:

A cylinder wall in an engine is under high temperature and high pressure, with the piston and piston rings sliding at high speeds. In particular, since longer service life is required of engines, forging cylinder that have excellent wear-resistant properties are only used for cylinder parts.

We can provide the following liners: GARDNER DENVER: PZ-7, PZ-8, PZ-9, PZ-10, PZ-11;

IDECO: T–500, T–800, T–1000, T–1300, T–1600a

Model No.:F-1300 Mud Pump

Production Capacity:50000 pcs/Year

Delivery Date:25days after the deposit re...

Certification:api 7k

Origin:China

Material:Forged steel

Structure:Piston Pump

Fuel:Diesel

Application:Well drilling

Means of Transport:Ocean,Land,Air;EXPRESS

Packing:Polywood case or steel cart...

Type:Others

Brand Name:KINGWELL

Model:F-500,F-800, F-1000,F-1300,...

Theory:Reciprocating Pump

Usage:Oilfield

Power:Hydraulic

Pressure:High pressure

------------------------------------------------

1. mud pump premium chromium liners

premium chromium liners;

Outer #45 forge steel, inner- 27% Cr.

All items made by API 7K standard

Liners have Four types: premium chromium liners/ceramicliners/chromium-plated liners/ hardened liners

All items are manufactured to API 7K quality standards.

Premium Liners: made witha high chrome/iron sleeve or bi-metal sleeve into a forged steel hull.

Ceramic Liners: combinethe strength of a forged steel outer shell with the abrasion andcorrosion resistance of a ceramic inner sleeve.provide zirconia sleeves as wellas alumina sleeves.

Chromium-Plated Liners: made from premium forged steel with the core plated by chrome.

Hardened Liners: these liners are hardened and heat treated under strict quality control to a minimum of 60RChardness. Each liner is honed to amirror-like finish for smooth.

The HRC can be from 60-64.

All liners are used for mud pump of long life.

2. Features of Mud pump Liners:

Liners are the main damageable parts in mud pumps for development drilling. The ceramic liner (zirconium and other compound materials) has the features of long service life time, wear-resistance and erosion-resistance. Its average life time ismore 5 times longer than the metal cylinder. Honestly, its own weak point is that there could be some fracture when the ceramic cylinder is impacted violently by other object. To guarantee the safe operation of the components and avoid breaking the ceramic liners, the following safety guidelines should be noted before installation:

(1) When installing the cylinder, it is better to use the special tool or follow the instruction below;

(2)Strictly prohibit flinging knocking or impacting the cylinder, if you need to put down, you shouldmove it as slowly and careful as you can;

(3) Strictly prohibit hitting ceramic cylinder with hammer or other heavy objects (including the metal shuck of the cylinder). When hitting, wood or other materials should be used asbuffer cushion;

(4) When you use hammer orother heavy objects to hit or strike the cylinder (especially for pressure cap,piston crown, piston rod), you should control the appreciated angle and force.Otherwise, the impact force which has been transferred to the cylinder willpossible fracture the ceramic liner of cylinder;

(5) Before the installationofpiston, you should check whether there is any damage on the metal shuck ofpiston crown. There should be at least 0.20mm installation clearance between themaximum outer diameter of the piston and inner diameter of ceramic liner,otherwise, ceramic liner could possible be damaged;

(6) After the installation,the side-friction between the metal part of piston and ceramic wall of thecylinder should be avoided. If it does happen, you should rectify as quickly asyou can

Bimetal Liner

Bimetal Liner Of Mud Pump

Application

Bimetal liner is used as a kind of mud pump fluid end accessories in the oil drilling industry.

Features

Our bimetal liner, API complaint, provides wear-resistant outer sleeve and high chrome corrosion-resistant inner sleeve. The high chrome liner has high rigidity of HRC≥61-64 after heat treatment.

Advantages

The bimetal liner offers long service life of about 800 hours, which is 2 to 3 times the lifetime of common ones in severe

Ceramic Liner

Ceramic Liner Of Mud Pump

Applications

The ceramic liner is used as a kind of mud pump fluid end parts in the oil drilling industry.

Features

Compared with the metal liner, the ceramic liner is wear and corrosion resistant and has extended working life. The ceramic liner helps reduce drilling cost and labor intensity. Made of internationally advanced, new material toughened zirconium oxide, the liner provides fracture toughness of K10-15Mpa (10 times that of the traditional one), and bending strength of σ600-800Mpa. The ceramic liner has excellent wear and corrosion resisting properties, with the Weber number being m18 and the elastic modulus of E200Gpa.

Advantages

The ceramic liner is the best choice for high pressure mud pumps. It is manufactured strictly in accordance with specific technical standards by use of advanced processing techniques. The ceramic liner comes in various specifications, which come in Φ150~180×310~440mm.

Valve Assembly

Valve Assembly Of Mud Pump

Application

Valve assembly is used as a kind of mud pump fluid end parts in the oil drilling industry.

Materials

Valve assembly is mainly made of high-quality alloy steel such as 20CrMnTi, 20CrNiMo, etc., which drastically exceeds the SY standards.

Advantages

The valve rubber of the valve assembly is made of new type high polymer materials to ensure superior performance, strong impact resistance under high temperature and high pressure.

Piston Assembly

Piston Assembly Of Mud Pump

Application

Piston assembly is used as a type of mud pump fluid end accessories in the oil drilling industry.

Materials

The main body of the piston assembly is made of forged steel 45# or 40Cr, and the piston cup and rubber are of high polymer materials.

Advantages

In order to accommodate every drilling need in various oil fields, we at KINGWELL have developed superior piston assembly for customers. Our piston assembly offers the advantages of reliable performance, strong wear and hydrolysis resistance under high temperature and high pressure.

Piston Rod

Piston Rod Of Mud Pump

Applications

Piston rod, as a kind of mud pump parts, is used as a fluid end accessory in the oil drilling industry.

Features

The piston rod is made of structural alloy steel, which goes through tempering heat treatment to achieve superior mechanical performance. The surface of the piston rod can be treated through phosphatization or galvanization.

Safety Valve

Safety Valve Of Mud Pump

Application

Safety valve is used as a mud pump fluid end accessory in the oil drilling industry.

Function

The safety valve serves to guarantee smooth operation of a mud pump within rated working pressure range.

Features

The safety valve offers easy reset, flexible operation, small bearing area, and high universality.

Valve Module

Valve Module Of Mud Pump

Application

Valve module is used as a kind of mud pump fluid end parts in the oil industry.

Advantages

The valve module is made by forging superior structural alloy steel, with no cracks or other flaws. It is fully compliant with API standards

Pulsation Dampeners

The pulsation dampeners shall be installed properly to reduce the pressure fluctuation and smooth the liquid flow. In order to extend the lifespan of the air bag, it is highly recommended to maintain the suggested proportion of the pump pressure to the pre-charge pressure of the air bag for the pulsation dampeners. Generally, the pump pressure shall be 2/3 that of the discharge pressure and no more than 4.5MPa.

Warning

1. Compressed nitrogen or compressed air shall be used for air charging. It is prohibited to utilize flammable and combustible gas such as compressed oxygen or hydrogen.

2. During maintenance, the pump pressure and the pressure inside the pulsation dampeners shall be zero. Since the residual pressure is generally small and can not be indicated on the pressure gauge, user shall confirm the pressure carefully to avoid accident caused by low pressure.

Extension Rod

The extension rod is an important part for the power end of mud pump in oil drilling. Produced by KINGWELL Company, it is forged from high quality alloy steel. High mechanical performance of the mud pump parts can be achieved through heat treatment. After being processed by CNC machine, this pump rod is ensured with precise geometric size. It is chrome plated with one-sided chrome thickness of over 0.1mm for increased abrasion resistance and extended service life of the alloy steel rod.

Crosshead

The crosshead is a vital part for the power end of mud pump in petroleum drilling. It acts as a pump component for connecting a piston with the extension rod. This mud pump part plays a guiding role. Its size precision decides the stability of operation of the whole mud pump. The crosshead assembly produced by KINGWELL Company is precisely forged from ductile cast iron beyond the industrial standard, which provides improved mechanical properties and elongation. Through heat treatment and parkerizing process, it eliminates the internal stress generated from the casting process and also increases its corrosion resistance. The crosshead centerline is determined prior to CNC machine processing. The error of all finishing size from the centerline has to meet the requirement of the drawing. In this way, the coaxially of the crosshead and the stability of both geometric size and power supply can be strictly guaranteed. The crosshead assembly covers a full range of BAOSHI, QINGSHI and LANSHI brand pumps. Both metric and imperial accessory products can be provided to meet the requirement of customers.

Upper and Lower Valve Guide

Upper and lower valve guides are important parts for the fluid end of mud pump in oil drilling. The upper type acts as a connector of valve spring and valve cover inside the hydraulic cylinder. It plays a guiding role in valve operation. The lower one is a connector of valve spring and hydraulic cylinder inside the cylinder. It has the function of fixing and guiding the valve operation.

Cylinder Head

Manufactured from domestically famous medium carbon alloy steel, the cylinder head has outstanding mechanical performance and wear-resistant property. The hammer forging, as well as the ultrasonic flaw detection technology, effectively eliminates the crack caused by porosity of metal structure. Our alloy steel cylinder head is machined with advanced CNC machine tool to ensure the small tolerance and good stability for installation. Apart from that, the precisely controlled heat treatment helps us achieve mechanical strength and hardness conforming to the requirement for mud pump.

Working Principle

The cylinder head is an important part for the inlet and outlet of fluid end valve housing. It is generally assembled to the flange of the valve housing. The bottom of the cylinder lid is installed against the positioning plate and the plug, playing the function of fixing.

Installation

User shall place the positioning plate into the hole at the pump head in case the installation of valve body assembly of the inlet and the guide apparatus is completed. In the meantime, the sealing ring of the cylinder head shall be put on the plug of the product. The outside of the sealing ring and the plug of the cylinder cover shall be smeared with light oil. Afterwards, push the plug into the opening of the fluid end and smear the thread of the product with lubricating grease. Finally, user shall screw in the thread into the cylinder head and fasten it with the fastening tool and hammer.

Flashboard Assembly

The flashboard assembly, also called positioning plate assembly, is an important component for the fluid end of mud pump in petroleum drilling. It has the function of longitudinally fixing the guide and horizontally fixing the cylinder head assembly for a hydraulic cylinder. Flashboards made by KINGWELL Company cover a full range of BAOSHI, LANSHI and QINGSHI brand pumps. All of them adopt high grade alloy carbon steel made by domestic steel plants. They have experienced the CNC cutting, blanking, heat treatment and CNC machining process, which ensures the geometric size. Some models of the product are added with copper blocks in order to increase the abrasion resistance of both flashboard and hydraulic cylinder end face. As mud pump accessories, they are well received by clients from numerous markets.

Valve Cover

Scientifically designed, the valve cover is made of first class medium carbon alloy steel from domestically famous brand, for excellent mechanical property and good resistance to abrasion. To avoid the defection such as crack caused by porosity of metal structure, we particularly manufacture the mud pump part with free forging and ultrasonic flaw detection technology. The advanced CNC machine tool enables accurate dimension of the valve cover. By virtue of the precise control on heat treatment, the mechanical strength and the hardness of the valve cover are in compliance with the requirement for mud pump working environment.

Working Principle

The valve cover is an important part for the inlet and outlet of valve housing for fluid end. The bottom of the mud pump valve cover is connected to the valve body guider, to ensure the airtightness and the stability of the water outlet.

Installation

Firstly, put the seal ring of the product in the hole of the valve housing. Secondly, user shall smear sealing element and the thread with lubricating grease. Finally, the valve cover shall be fastened with the fastening tool and the hammer.

Wear Plate

The wear plate is a kind of pump accessory for the fluid end of mud pump in oil drilling. It has the function of sealing and pressure maintaining for a hydraulic cylinder. All wear parts made by KINGWELL Company adopt high end alloy carbon steel made by domestic steel plants. These wear resistant steel plates have experienced the high temperature forging, heat treatment and CNC machining process, which guarantees geometric size, sealing performance, increased abrasion resistance and durability. Different models and types of wear plate (liner) products and related jackscrews can be offered upon request.

Cylinder Flange

The cylinder flange is a vital part for the fluid end of mud pump in petroleum drilling. As a mud pump element, it plays a role in fixing and sealing the hydraulic cylinder head plug and cover. A high-grade proper flange is adopted for improved cylinder head plug loading condition, increased bearing capacity and extended lifespan. The product made by KINGWELL Company covers a full line of BAOSHI, LANSHI and QINGSHI pumps. It is manufactured from high quality alloy carbon steel by domestic steel plants. This carbon steel flange withstands the high temperature forging, heat treatment and CNC machining process for guaranteed geometric size as well as increased wear resistance and durability.

Valve Cover Flange

The valve cover flange is important to the fluid end of mud pump during the oil drilling process. It is an oil drilling tool that has the function of fixing and sealing the hydraulic cylinder head plug and cover. A superior quality proper flange is utilized for improved cylinder head plug loading condition, increased bearing capacity and extended service life. The mud pump part made by KINGWELL Company covers all kinds of BAOSHI, LANSHI and QINGSHI brand pumps. It adopts top grade alloy carbon steel manufactured by Chinese steel plants. As a fluid end part, this product is completed through high temperature forging, thermal treatment and CNC machining in order to guarantee geometric size and also improve durability and wear resistance.

Pressure Gauge

The Yt-100 pressure gauge is made of stainless steel. This pressure measuring device can be installed at axial direction or radial direction. The screw thread of the pressure meter makes the installation of the product easier. Our stainless steel pressure gauge is strictly manufactured according to IP 65 protection level. The measuring accuracy of the pressure gauge is up to 1.5%.

New Type Core Box

Brief Introduction

The core box is a container used to store cores which are pulled out by a drill. Rock cores obtained from a drill hole are put into a core tray sequentially and cataloged timely by geologist. The product would be numbered and stored in a core library.

Features of New Type Core Box

The new type core box is made from new synthesized materials by high pressure injection molding. It is obviously superior to ordinary plastic core tray regarding the resistance to shock, aging, high temperature, extremely cold climate and other aspects. This product is categorized into 2 series and 8 sizes. It is equipped with box cover, flash-board, chains and other accessories. Our drill core box is reliable equipment of long-term storage and convenient transportation for geological exploration and oil exploration.

2S Gear Oil Pump

2S Gear Oil Pump

The 2S gear oil pump is the main element for the lubricating system of the power end for mud pump. This lubricating oil pump is usually installed on the pressure lubrication system, offering lubricating oil for crosshead, crosshead bearing, extension rod, etc.

Corrugated Bellows

Corrugated Bellows

The corrugated bellow is a kind of tubular elastic rubber product which is connected using a corrugated piece for the mud pump from LANSHI and QINGSHI factories. It plays a role in separating and sealing between the fluid end and the power end of a mud pump. Dezhou KINGWELL Petroleum Machinery Co., Ltd. is capable of producing different models of corrugated pipes. Our company holds an independent rubber accessory factory and the first self-invented rubber injection machine in China. After injection, the raw material can be vulcanized and completed in an integrated mould for only once, which ensures both performance and lifespan of the corrugated bellow.

Plug, Cylinder Head Sealing Plug

Plug

The plug is an important part for the fluid end of mud pump in oil drilling. Its front part is equipped with cylinder head (valve cover) sealing ring for the sealing and pressure maintaining of a hydraulic cylinder. A top-grade suitable plug is adopted to improve the cylinder head plug loading condition and also increase the bearing capacity and service life. Plugs made by KINGWELL Company cover a full range of pumps from BAOSHI, LANSHI and QINGSHI factories. All of them adopt high quality alloy carbon steel made by domestic steel plants. They are finished by means of high temperature forging, heat treatment and CNC machining so as to achieve guaranteed geometric size, sealing performance, increased durability and wear resistance.

Locking Clip

Locking Clip

The locking clip is a part of the fluid end of F series mud pump from BAOSHI factory. It has the function of fixing and supporting the guide inside a hydraulic cylinder. The product produced by KINGWELL Company is made from superior quality brass. After being heated, it is bended and completed with specialized equipment for increased wear resistance and extended service life.

Stuffing Box, Diaphragm Stuffing Box

Stuffing Box

The stuffing box is an important component for the power end of mud pump in oil drilling. It plays a crucial part in sealing the lubricating system and the operation inside power end. Its housing produced by KINGWELL Company is precisely cast from ductile cast iron beyond industrial standard for improved mechanical properties and elongation. The adoption of heat treatment and phosphating technology helps eliminate the internal stress generated from the casting process and also improves corrosion resistance. After CNC finish machining, it is tightly assembled with wear-resistant rubber, vulcanized oil seal and sealing ring, as well as the nylon oil seal ring made by the machining center. In this way, the service life of sealing elements inside the stuffing box assembly could be greatly extended. This product is well received by clients.

Cylinder Retaining Ring, Liner Locking Ring

Cylinder Retaining Ring

As its name implies, the cylinder retaining ring is a part of fluid end for fixing the cylinder sleeve.

Cylinder Head Plug

Cylinder Head Plug

The cylinder head plug is a vital part for the fluid end of mud pump in petroleum drilling. A high quality suitable plug is adopted for improved loading condition as well as increased bearing capacity and lifespan. The product made by KINGWELL Company covers a full range of BAOSHI, LIANSHI and QINGSHI brand pumps. It is derived from top grade alloy carbon steel made by domestic steel plants. Besides, this product is completed with high temperature forging, heat treatment and CNC machining technology so as to guarantee the geometric size, sealing performance as well as increased durability and abrasion resistance.

Piston Rod Nut

Piston Rod Nut

The piston rod nut is a kind of anti-loosening nut for the end of piston rod. In common with the material of piston rod, it is made from superior quality alloy steel. The head of the product manufactured by KINGWELL Company is filled with a wear-resistant high strength nylon gasket so as to prevent rod thread from abrasion or being impacted by mud when in use of a piston rod. After heat treatment, this product offers better mechanical property. All models of piston rod nuts in metric and imperial units from BAOSHI, LANSHI, QINGSHI and other factories can be produced to meet the needs of customers.

Discharge Filter Screen Assembly

Discharge Filter Screen Assembly

The discharge filter screen assembly is a main component of the outlet for the fluid end of mud pump in petroleum drilling. It is composed of filter screen assembly, housing assembling as well as sealing ring, end cover and other accessories. The integrated formed filter screen housing made by our company adopts casting technique. The filter screen assembly is manufactured from superior quality alloy steel and assembled after CNC machining. This not only provides excellent corrosion resistance and pressure resistance, but also helps customers increase production efficienc

Ceramic liner is composed of bearing metal sheath and ceramic liner with high wear-resistance, and the integrated cylinder liner is mechanically processed and assembled.

Product features

I. Excellent abrasion resistance: There are various sharp particles as lithic quartz sand, iron ore, iron etc., in the high pressure mud during drilling. These particles have high hardness and good abrasion resistance features that will cause grinding and erosion on cylinder surface. Therefore, Cylinder liner materials have higher requirements on abrasion resistance. Compared with the traditional double metal cylinder liner, the life of the ceramic cylinder liner manufactured by the company is improved by more than 10 times and the service life of it is up to 4000-10000 hours.

II. Good surface quality: The surface quality of the ceramic material has a great influence on the service life. The KWOM series ceramic liner prepared by the company has a uniform microstructure and has good smoothness and gloss after being processed many times. Compared with the single phase alumina ceramics, the toughness is improved greatly and abrasion resistance and service life are also improved obviously due to good surface quality and reduction of water for lubrication.

III. Superior comprehensive mechanical properties: KWOM series ceramic cylinder manufactured by the company has features of excellent corrosion resistance, high temperature resistance and abrasion resistance of the ceramic materials and the properties of material strength, hardness, toughness and thermal shock resistance are greatly enhanced based on the phase transformation toughening technology so that it has superior mechanical properties to be suitable for the work in the drilling mud or other corrosive conditions. For example, it could be applied to some areas as hazard drilling environment as deep petroleum storage and geological structure and offshore oil, gas and shale gas exploration.

IV. Lower cost: Compared with the traditional double metal cylinder liner and single phase alumina cylinder, the repair costs, labor costs, the cost of storage and the transportation cost could be reduced and the work efficiency could be improved due to improvement of the comprehensive properties by using the ceramic cylinder liner manufactured by the company.

Technical parameters

|

Item |

KWOM-ZTA Series |

KWOM-TZP Series |

|

Composition |

Aluminum oxide, zirconium oxide, yttrium oxide |

Zirconium oxide, yttrium oxide |

|

Volume density(g/cm³) |

≥4.25 |

≥6.00 |

|

Bending strength(MPa) |

≥560 |

≥800 |

|

Fracture toughness(MPa.M1/2) |

≥5.83 |

≥10.00 |

|

Rockwell hardness(HRA) |

≥91 |

≥89 |

|

Work surface roughness(μm) |

≤0.26 |

≤0.20 |

|

Compressive strength(MPa) |

≥3000 |

≥3000 |

|

Wear resistance(cm3) |

0.28 |

0.20 |

|

Thermal shock resistance |

≥450℃ |

≥450℃ |

Cost analysis of Ceramic liners and Double-metal liners

|

Purchasing Cost |

|

|

Continuous

working time |

Service life of a liner |

Purchasing cost of a linear |

Required

quantity |

Total cost |

Cost per hour |

|

Double-metal liners |

4000 h |

500 h |

1200 RMB |

8 |

9600 RMB |

2.40 RMB |

|

Ceramic liners |

4000 h |

≥4000 h |

5180 RMB |

1 |

5180 RMB |

1.30 RMB |

|

Maintenance Costs |

|

|

Continuous

working time |

Service life of a liner |

Replacing times |

Replacing cost |

Total Cost |

Cost per hour |

|

Double-metal liners |

4000 h |

500 h |

8 |

2000 RMB |

16000 RMB |

4.00 RMB |

|

Ceramic liners |

4000 h |

≥4000 h |

1 |

2000 RMB |

2000 RMB |

0.5 RMB |

Production scope of Ceramic Liners

|

Brand of mud pump |

Types of ceramic cylinder liner |

|

BOMCO |

F-350/500 |

F-800/1000 |

F-1300/1600 |

F-1600HL |

F-2200HL |

|

EMSCO |

FB-1000 |

FB-1300/1600 |

F-350/500 |

F-650 |

F-800/1000 |

|

F-1300 |

F-1600 |

DB-550 |

D-300 |

D-700 |

|

GARNDER-DENVER |

PZ-7 |

PZ-8/9 |

PZ-10/11 |

PZ-L |

PA-8 |

|

FY-FXD |

FO-FXO |

FD-FXX |

FG-GXG |

|

|

NATIONAL |

7-P-50 |

8-P-80 |

9/10-P-100 |

12-P-160 |

14-P-220 |

|

OILWELL |

A-600-PT |

A-850-PT |

A-1100-PT |

A-1400-PT |

A-1700-PT |

|

IDECO |

T-500 |

T-800 |

T-1000 |

T-1300 |

T-1600 |